ENOCH Auto Body Spray

Intelligent Control Platform Solution

A Digital-Intelligent Solution for Auto Body Spray Platform Enterprises

Addressing the core pain points of auto body spray platform enterprises—"difficult multi-store coordination, inconsistent standards, and poor data connectivity"—ENOCH has developed a dual-end architecture of "Platform End + Store End". Using a "one-leads-many" model, it enables end-to-end standardized management and real-time data interoperability, comprehensively empowering partners for efficient multi-store operations from business execution to headquarters oversight.

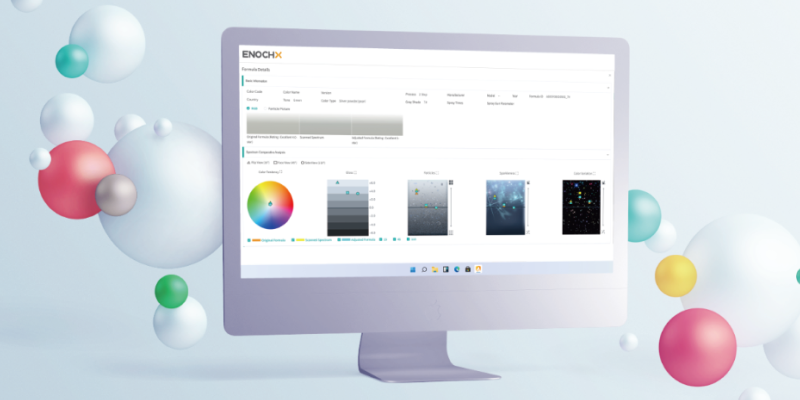

Intelligent Color Matching Service

Enhancing Spray Quality and Efficiency Across Stores

Targeting the challenges of "inaccurate and slow color matching" in spray shops, ENOCH provides precisely adapted color matching solutions. Currently, it offers deep support for BASF Glasurit 90 Series and Basely Waterborne Paints, paired with high-precision spectrophotometer and AI algorithms to quickly capture car paint data and directly access exclusive formula databases, avoiding color deviations due to mismatched paint types

Low-Barrier Precision Color Matching

No longer reliant on "veteran technicians." Store technicians can generate accurate formulas within 10 minutes using a spectrophotometer + Intelligent matching algorithm + cloud-based micro-adjustment algorithms.

Remote Algorithm Support from Headquarters:

If a store encounters complex color matching needs, it can connect remotely to ENOCH’s Color Lab for guidance from headquarters-level technical teams on parameters, preventing customer loss due to technical bottlenecks and ensuring satisfaction and on-time delivery.

Flagship Edition with Color Lab System

The platform end can establish its own core color data management system, enabling color development, formula management, and store-level color matching services

Dual-End Spray Business Management System

Making Multi-Store Operations "Visible and Meticulously Managed"

Leveraging the Intelligent Spray ERP Management System, ENOCH builds a business management system of "platform-end coordination + store-end execution," focusing on core scenarios in the spray industry:

End-to-End Spray Work Order Control

Stores manage work order statuses in real time (vehicle intake, color matching, spraying, delivery), while the platform end monitors progress and handles exceptions.

Panel-Level Cost Control

The system automatically captures panel count and damage level for each order, combining material standards to generate cost analysis reports. The platform end can compare multi-store panel processing efficiency, while stores know exactly "how much paint and materials each panel requires," eliminating waste.

Dynamic Paint Inventory Management

Real-time sync of colorant inventory across stores enables platform-end monitoring and cross-store transfers. Stores receive automatic low-stock alerts and real-time reordering, improving inventory turnover by 30%+.

breaking down multi-store information silos

User management, equipment records, procurement-sales-inventory accounting, and more ensure full control over "personnel, equipment, materials, orders, and finances"

Dual Systems Empowerment: Refined Management of Store Operations and Production

Refined Smart Operation Management Service System

Based on real operational data, it provides actionable tools for platform enterprises:

Multi-Dimensional Operational Analysis

Automatically aggregates store data (revenue, work order completion rates, material waste rates) for comparative reports, identifying inefficiencies and optimization directions.

Key Node Alerts

Automatic warnings for overtime work orders, low inventory, equipment failures, etc., enabling direct oversight from the platform end to prevent minor issues from escalating.

In-Depth Operational Insights

Analyzes market trends, customer needs, cost control, and profit analysis for comprehensive business intelligence.

High-Efficiency Transparent Workshop System

Store-End Execution, Headquarters Coordination

Store End-Real-Time Production Pace Control

Stores can monitor work order progress dashboards and equipment status via the system, enabling on-site adjustments to personnel and equipment allocation to reduce downtime.

Platform End- Global supervision of all stores’ workshop data

analyzing low workstation utilization and lengthy processes, enabling onsite optimization and cross-store experience replication.

Dual-End Collaboration + Full-Chain Support

Ensuring Unified Standards and Data Connectivity

1.Software: Precision-Matched Dual-End Functions

1)Platform End – Multi-store order coordination, cross-store inventory allocation, operational data analysis, standard setting and supervision.

2)Store End – Executes spray orders, performs panel-level cost accounting, schedules workshop tasks, and manages local equipment and inventory. Real-time data synchronization ensures unified process standards and service procedures across all stores.

2. Hardware + Materials: Foundation for Multi-Store Operations

1)Hardware Compatibility:Standard ENOCH smart colorimeters, electronic scales, barcode scanners; optional centralized dust extraction systems and spray robots. Stores configure flexibly based on capacity; the platform end uniformly monitors equipment data.

2)Material Assurance:Supplies BASF Glasurit 90 / Basely series colorants, clear coats, and auxiliary materials. Platform-end centralized procurement reduces costs; stores access inventory directly, ensuring traceable and consistent quality.

3. Operational Support

ENOCH’s brand experience empowers platforms to implement standards (e.g., process standards, technical training, service systems).

Choosing ENOCH’s Platform means opting for "Standardized Multi-Store Management and Digital-Intelligent Efficiency"—whether managing 10, 50, or 500 stores. Through the "Platform-End Coordination + Store-End Execution" model, real-time data exchange and precise control make multi-store operations easier and more profitable for platform enterprises.

Book a ConsultationNews

Tel:+86 400-996-0171

Email:enoch@enoch-car.com

Address:16th Floor, Building T5, U.S. Center, EFC,Yuhang District, Hangzhou City, Zhejiang Province, P.R.China

ZIP Code:311121

Zhejiang Public Network Security No.33011002015331

Contact: 400-996-0171